DIRECTIONAL CONTROL VALVE

A hydraulic directional control valve is a device used in hydraulic systems to control the flow of hydraulic fluid (usually oil) and to direct it to specific actuators or sections of a hydraulic circuit. These valves can control the direction of fluid flow, starting, stopping, and regulating the flow rate.

Here are some key points about hydraulic directional control valves:

Direction Control: These valves determine the direction of fluid flow in a hydraulic system. They can be configured to allow fluid to flow in one or multiple directions.

Actuation: Directional control valves are typically actuated either manually, mechanically, electrically, pneumatically, or hydraulically. The method of actuation depends on the specific application and requirements of the system.

Types: There are several types of directional control valves, including spool valves, poppet valves, rotary valves, and slide valves. Each type has its own advantages and is suited to different applications.

Functions: Directional control valves can perform various functions, such as on/off control, proportional control (where the flow rate is proportionate to the input signal), and pressure control (maintaining a set pressure level in a system).

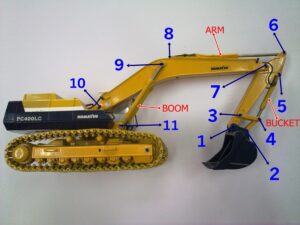

Applications: These valves are used in a wide range of hydraulic systems, including industrial machinery, mobile equipment (such as excavators and loaders), agricultural machinery, and aerospace systems.

Overall, hydraulic directional control valves are essential components in hydraulic systems, allowing for precise control over the movement of hydraulic actuators and machinery.