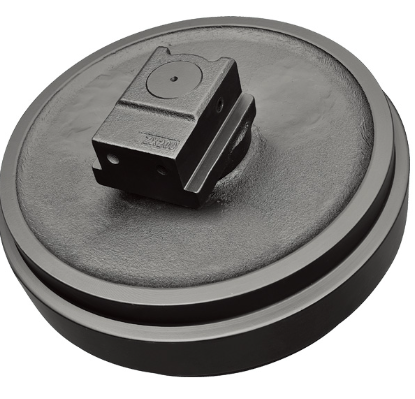

The idler in an excavator is an essential component of the track system, helping to support and guide the tracks while ensuring proper operation. Here are five key functions of the excavator idler:

- Track Tension Control: The idler helps maintain proper tension on the track, ensuring that it remains tight and engaged with the sprocket and rollers. Proper track tension is critical for efficient movement and preventing track slippage or derailment.

- Track Guide: The idler acts as a guide for the track, helping to keep it aligned and on course. It helps prevent the track from veering off track or becoming misaligned during operation, ensuring smooth movement and reducing the likelihood of premature wear.

- Absorbs Track Stress: The idler absorbs some of the stresses and loads exerted on the track system, especially during turns or when the excavator is operating on uneven terrain. It helps distribute these forces evenly across the track, contributing to the overall stability of the machine.

- Prevents Track Wear: By keeping the track aligned and properly tensioned, the idler minimizes the wear and tear on the track, sprockets, and other components. This helps extend the lifespan of the track system and reduces maintenance costs over time.

- Supports the Undercarriage System: The idler is part of the undercarriage assembly and contributes to the overall stability and balance of the excavator. It supports the weight of the machine and assists in distributing the load across the tracks for more effective traction and movement.

The idler is crucial for ensuring the efficient operation, durability, and safety of the excavator’s track system, allowing for smooth and controlled movement on a variety of surfaces.