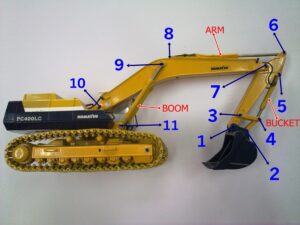

The excavator harness wire is an essential part of the electrical system, enabling proper operation and communication between various electrical components and systems on the machine. Here are five key functions of the excavator harness wire:

- Power Transmission: The harness wire delivers electrical power from the battery and alternator to various components such as the engine, lights, sensors, and control systems. It ensures that all parts requiring electrical energy receive it to function properly.

- Signal Communication: The harness wire transmits signals between control systems, sensors, and actuators. It enables communication between the operator’s controls and the excavator’s electronic systems, ensuring smooth operation of features like engine speed, hydraulic control, and safety monitoring.

- System Integration: The harness wire connects different electrical systems within the excavator, including the engine, transmission, lighting, and safety systems. This integration allows for coordinated operation and functionality across the entire machine.

- Safety Monitoring: The harness wire is connected to various safety sensors and alarms, such as those for engine temperature, oil pressure, and hydraulic fluid levels. It helps to monitor these critical parameters and relay warnings to the operator when necessary to prevent damage or accidents.

- Fault Detection and Diagnostics: The harness wire supports diagnostic systems by transmitting data about the performance and health of the excavator’s electrical components. If there is a fault, the harness wire helps send error codes or signals to alert the operator or maintenance crew, allowing for faster troubleshooting and repairs.

In summary, the excavator harness wire plays a crucial role in providing power, facilitating communication between systems, ensuring safety, and supporting diagnostic capabilities to maintain efficient operation and performance.