1. Engine Cranking: The primary function of the starter is to crank or turn the engine over when the operator turns the ignition key. This initial cranking action is necessary to kick-start the engine and get it running.

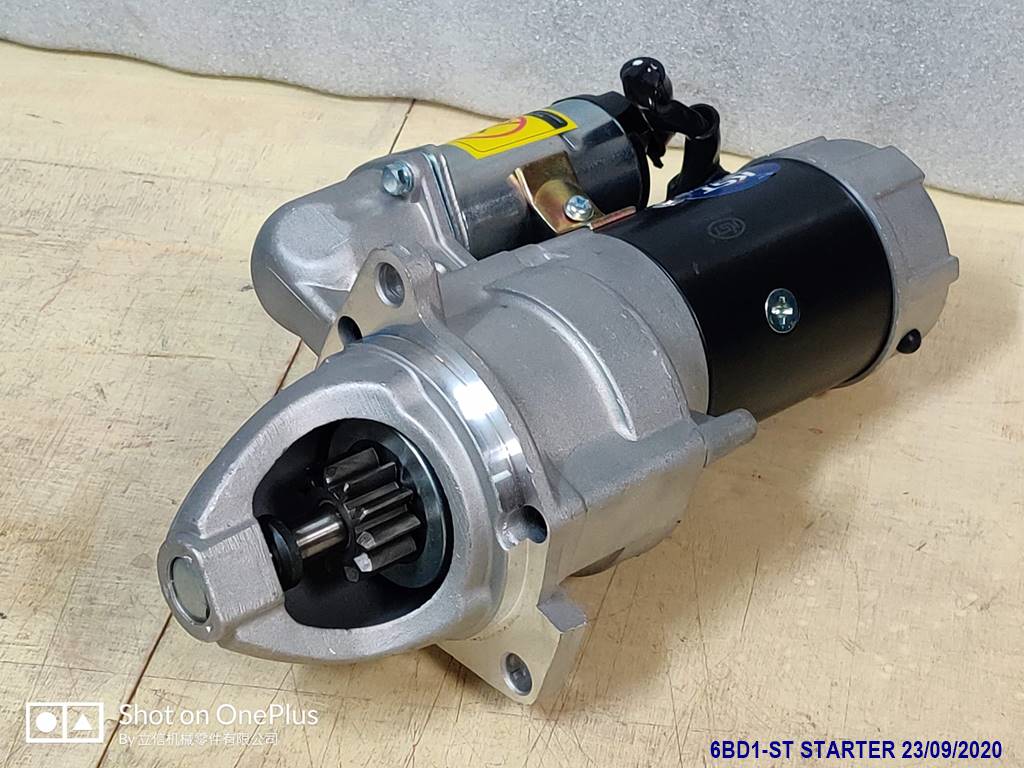

2. Powering the Engine: The starter motor is an electric motor that draws electrical power from the excavator’s battery. When the operator activates the ignition, electrical current flows to the starter, causing it to rotate. This rotation is then transmitted to the engine’s flywheel.

3. Flywheel Engagement: The starter motor engages with the engine’s flywheel, which is a large, toothed wheel connected to the crankshaft. As the starter turns the flywheel, it begins to rotate the engine’s internal components, allowing the combustion process to start.

4. Ignition of Fuel-Air Mixture: As the engine components start moving, the fuel and air mixture is introduced into the combustion chambers. The turning of the engine generated by the starter motor initiates the compression and ignition processes, leading to the combustion of fuel.

5. Starting the Engine: The combined action of the starter motor and the engine’s internal combustion process results in the engine coming to life. Once the engine is running, the starter disengages from the flywheel automatically.

6. Assisting Cold Starts: Starters are especially crucial during cold weather conditions when the engine might be more resistant to turning over. The starter provides the necessary mechanical force to overcome this resistance and start the engine