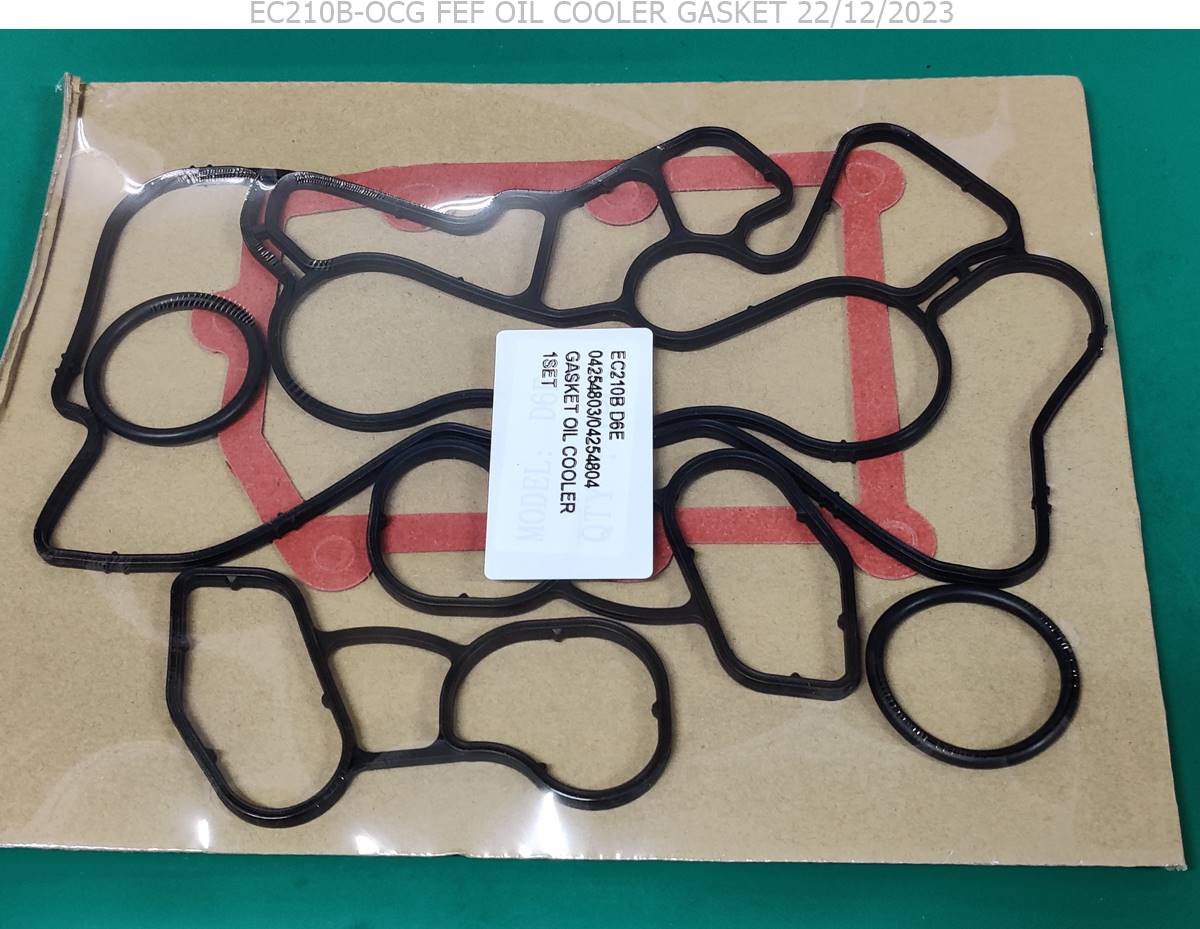

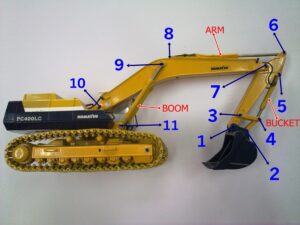

The oil cooler gasket in the EC210B excavator (or any similar machinery) serves several essential functions within the engine’s oil cooling system. Here are five key functions of the oil cooler gasket:

- Seals Oil Cooler Connections: The primary function of the oil cooler gasket is to provide a reliable seal between the oil cooler and the engine block or oil cooler housing. This prevents oil leaks and ensures the cooling system operates efficiently.

- Prevents Contamination: The gasket helps keep oil separate from coolant or other fluids in the oil cooler, preventing cross-contamination. This ensures that the oil remains free of impurities, maintaining the integrity of the lubrication system.

- Maintains Pressure: The oil cooler gasket helps maintain the required pressure within the oil cooler circuit. By providing a tight seal, it ensures the oil is properly circulated through the cooler without any loss of pressure, allowing for efficient heat exchange.

- Prevents Leaks: By sealing the oil cooler housing, the gasket prevents oil from leaking out of the system. This is crucial for maintaining proper oil levels and preventing the risk of engine damage due to low oil pressure or overheating.

- Thermal Management: The oil cooler gasket plays a role in ensuring effective heat exchange by maintaining proper alignment and sealing of the oil cooler. This helps regulate engine oil temperature, ensuring that it remains within optimal operating conditions to prevent overheating and ensure engine efficiency.

In summary, the oil cooler gasket is critical for maintaining a leak-free, pressure-stable, and efficient oil cooling system, contributing to the longevity and performance of the engine.